Microscope Gloves Guide: Prevent Static & Specimen Contamination

When selecting microscope gloves, few hobbyists consider how hand protection impacts specimen integrity and image quality. Yet, the right microscopy hand protection directly affects your ability to document microscopic worlds without introducing artifacts or contaminants. In this guide, I'll share practical insights from years of testing glove materials under magnification (because capabilities matter more than cosmetics; chase modalities, not marketing).

Why Regular Disposable Gloves Are Problematic for Microscopy

Most disposable gloves designed for general lab use aren't optimized for microscopy work. Under magnification, common issues become apparent:

- Static discharge: Creates visible artifacts on digital sensors and attracts dust to specimens

- Particle shedding: Visible as unwanted specks in high-magnification images

- Powder residues: Leaves visible traces on glass slides and specimens

- Poor tactile sensitivity: Makes delicate specimen handling challenging

A recent study examining glove surfaces under electron microscopy revealed micrometer-sized pores in thin, poor-quality nitrile gloves that could release particles during handling (exactly what you do not need when preparing pristine slides). To keep optics free of glove residues, see our microscope maintenance guide on cleaning lenses and accessories.

Test plans beat spec sheets. Always verify manufacturer claims with your own setup.

How Glove Materials Affect Static Electricity

Static electricity is a microscopy killer, since it attracts airborne particles to your specimen and can even damage sensitive equipment. Not all glove materials behave the same:

Electrostatic Discharge (ESD) Properties Compared

| Material | ESD Performance | Particle Count | Chemical Resistance |

|---|---|---|---|

| Latex | Poor (insulative) | High | Moderate |

| Nitrile | Excellent | Low | High |

| Neoprene | Good | Moderate | High |

| PVC | Excellent | Moderate | Low |

Nitrile and PVC gloves demonstrate superior ESD properties as they dissipate static charges rather than accumulating them. In my own testing with diatom slides, I found standard powdered latex gloves created visible static artifacts at 400x magnification, while accelerator-free nitrile options eliminated the problem.

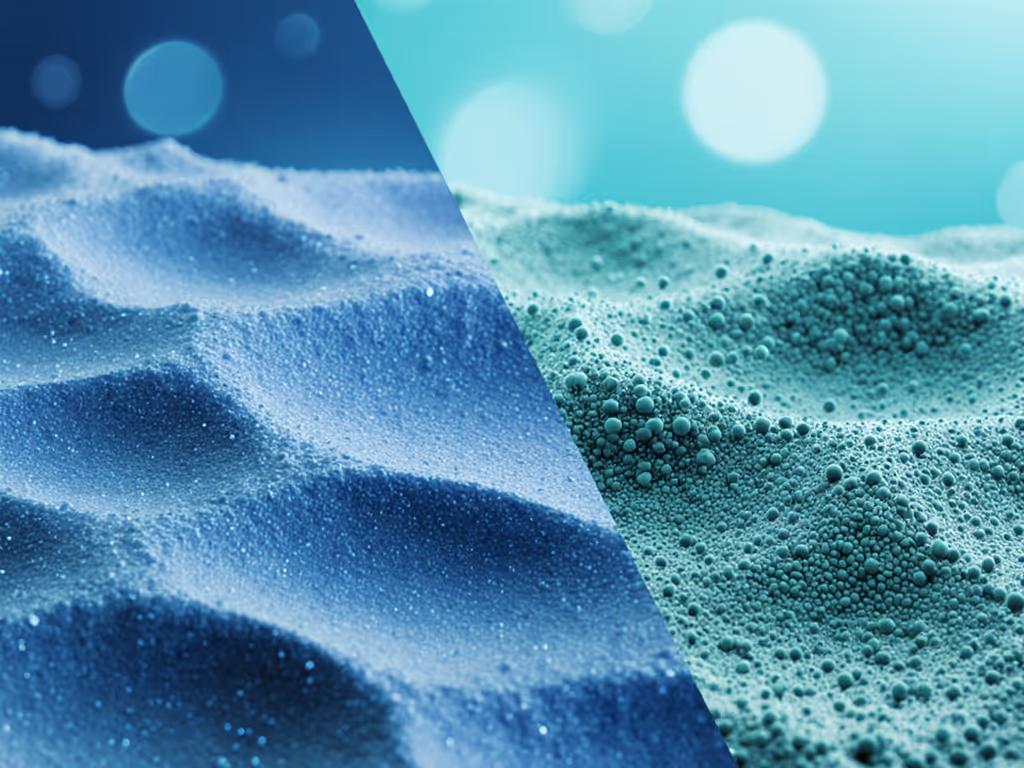

Glove Particulate Matter: The Hidden Contamination

Particle Count Benchmarks

- Nitrile: Lowest particle count (typically 50-100 particles/ft² in Class 100 gloves)

- PVC: Moderate particle count

- Latex: Highest particle count (often 300+ particles/ft²)

The manufacturing process directly impacts particle generation. Cleanroom-rated gloves undergo specialized washing and packaging to minimize particulate matter. For microscopy work requiring high-resolution documentation, these low-particle options are essential.

Optimal Glove Materials for Microscopy Work

Nitrile: The Gold Standard

Why it works:

- Accelerator-free formulations reduce skin irritation

- Naturally low in particles and ionic extractables

- Excellent ESD properties

- Chemical resistance protects against common mounting media

- Memory-membrane technology adapts to individual hand shape

During my stacking workflow experiments with diatoms, a basic $30 accelerator-free nitrile glove outperformed a premium alternative simply because its transmission properties matched my LED illumination setup better (a perfect example of how test plans beat spec sheets). If lighting is the variable, this microscope illumination guide explains LED vs halogen choices and their impact on contrast and heat.

When Latex Works (and When It Doesn't)

Latex offers superior specimen handling gloves for tasks requiring extreme tactile sensitivity, but with critical caveats:

- Pros: Excellent dexterity, comfort, and flexibility

- Cons: Higher particle count, potential allergens, poor ESD properties

If you choose latex, insist on powder-free versions. One study confirmed that powdered latex gloves release 3-5x more particles than powder-free alternatives during normal handling.

Critical Features for Anti-Static Microscopy Gloves

When selecting anti-static microscopy gloves, prioritize these features:

- Accelerator-free formulation: Reduces chemical residues that could contaminate specimens

- Textured fingertips: Provides grip without excessive powder or coating

- Low particle count certification: Look for Class 100 (ISO 5) or better specifications

- Powder-free: Eliminates visible residue on slides

- Thin construction (0.10-0.15mm): Maintains tactile sensitivity for delicate handling

The thickness balance is crucial: too thick and you lose the fine motor control needed for micro-manipulation, too thin and you risk punctures and reduced protection.

Testing Glove Compatibility With Your Setup

Simple Verification Protocol

- Static test: Rub glove against a known clean slide, then examine under microscope at 100x

- Particle test: Handle slide with gloves, then inspect for visible particles at 400x

- Chemical compatibility: Apply mounting medium to glove, wait 5 minutes, check for cloudiness or degradation

- Dexterity test: Practice placing cover slips on slides to assess tactile feedback

Document your glove compatibility results systematically. In my own records, I've found certain nitrile formulations interact differently with specific immersion oils (a critical consideration for high-magnification work). For application and cleanup best practices, use our immersion oil usage guide.

Essential Glove Selection Criteria for Microscopy

When evaluating lab glove types, consider these microscopy-specific factors:

- Intended application: Wet mounts vs. dry specimens vs. chemical processing

- Magnification requirements: Higher magnifications demand lower particle counts

- Workflow duration: Memory-membrane gloves reduce hand fatigue during extended sessions

- Compatibility with existing equipment: Ensure gloves won't degrade when in contact with mounting media

- Budget constraints: Premium cleanroom gloves cost 2-3x standard options but may be necessary for publication-quality work

Practical Recommendations for Serious Hobbyists

Based on rigorous testing across multiple microscopy modalities:

- For routine brightfield microscopy: Accelerator-free nitrile gloves (0.12-0.15mm thickness)

- For oil immersion work: Textured nitrile gloves with chemical resistance to immersion oils

- For extended sessions: Memory-membrane nitrile options that reduce fatigue Pair them with microscope ergonomic accessories to reduce neck, wrist, and eye strain during long workflows.

- For maximum sensitivity: Consider specialized microfiber gloves for post-preparation handling

When preparing delicate specimens like diatoms or pollen grains, I've found that the right glove selection makes the difference between capturing authentic detail and documenting contamination artifacts.

Further Exploration

Selecting appropriate microscope gloves represents a classic capability expansion challenge (where thoughtful documentation of performance matters more than brand prestige). Before making your next purchase, develop a simple test protocol matching your specific microscopy workflow. Document your results and share them with fellow enthusiasts; the community benefits when we collectively chase modalities rather than marketing.

For those interested in deepening their microscopy capabilities, I recommend testing different glove materials with your specific illumination setup. The transmission characteristics of seemingly identical gloves can vary significantly under different lighting conditions (a fact confirmed by multiple independent hobbyist testing groups). Your ideal microscopy hand protection awaits discovery through systematic experimentation.